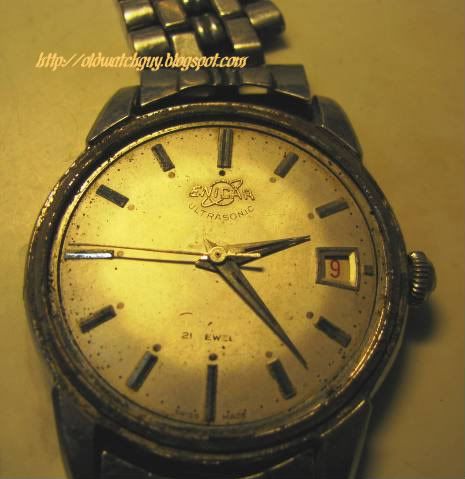

I don't know about the ultrasonic part but this is a simple date-only hand-wind using Enicar's 1010 movement/18,000bph, a simple and elegant movement from the sixties. No surprises but parts may be a problem.

The crystal is most likely original as the tapered loupe (magnifying bubble) matches the date apperture but sadly it is not usable. Bracelet is junk. Removing the bracelet revealed a lot of.......cheese!

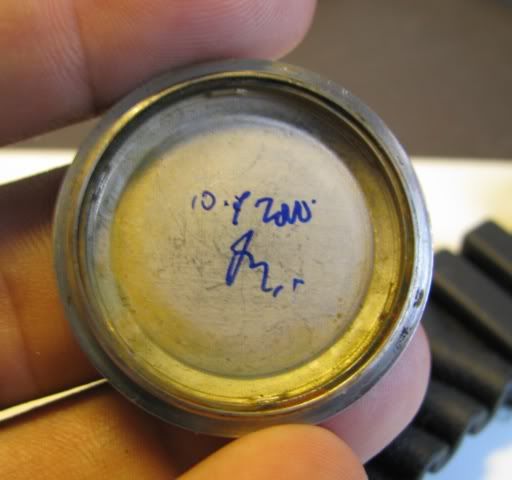

The case back is well worn with a lot scratches from previous attempts to open it. I must admit that my first attempt was also fruitless, my case-back openers would not budge it. Now what? A bigger hammer? Heat?....

Well in any scenario when you are faced with a problem, sit back and look at it again. In this case I applied some oil where the caseback screws into the case and put the watch away.

When I came back to it a few days later, the first thing I noticed was that the caseback was orientated nicely as it was exactly level with the crown, usually watch casebacks will end up in any possible angle after its screwed on tight, and you only see properly oriented caseback on snap-on type casebacks......hmmm.

On further inspection, I can see a little triangle pointing to the crown...getting closer..

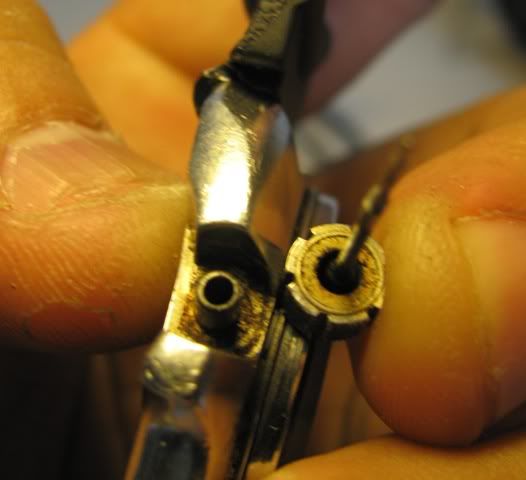

then I spy this little 'tang' at the bottom of the case back....yup, its a snap-on! a little pressure with a knife and bingo...!

From the scratches on the caseback it seems this watch has defeated a few other watchmakers as some of the scratches are quite deep.

The movement is pretty dirty and has seen water entry, the balance would move slowly, as if suspended in honey. Hopefully a clean and oil is all it requires.

The dial looked quite good under the badly cracked crystal, surprisingly.. a few spots and the letters '21jewels' are partially worn but its perfectly serviceable, the 'ULTRASONIC' has survived well. I especially like the tapered date window.

All was well under the dial too.. the date-wheel is OK, note the assymetrical dates which fit the tapered date-window.

Some general pics

no more wrist-cheese...

caseback cleaned up a bit

A strip-down, clean and oiling had this watch ticking away happily...

A real rough diamond.

Update 30th Sep 2010

Apparently the ULTRASONIC refers to the 'high-tech' method of cleaning the watch components prior assembly. See the ad posted in this post on the Time-zone forum (second ad down).

Update 2nd Oct 2010

.........and here